Load restraint best practices are essential for ensuring safety, preventing accidents, and protecting cargo during transportation. While general principles apply across industries, specific requirements and challenges vary. This comprehensive guide provides industry-specific tips to help you secure your loads effectively.

Understanding the Importance of Load Restraint

Before diving into industry-specific practices, it’s crucial to understand why load restraint is so important. Improperly secured loads can lead to:

- Accidents: Shifting cargo can cause vehicle instability, increasing the risk of rollovers and collisions.

- Injuries: Loose items can become projectiles during accidents, causing severe injuries to drivers and passengers.

- Cargo Damage: Shifting loads can damage goods, resulting in financial losses.

- Legal Consequences: Non-compliance with load restraint regulations can lead to hefty fines and penalties.

Load Restraint Best Practices by Industry

To effectively secure your loads, it’s essential to tailor your approach to the specific needs of your industry. Here’s a breakdown of best practices for various sectors:

Construction

- Secure heavy equipment and materials using chains, winches, and load binders.

- Employ anti-slip mats to prevent load shifting.

- Distribute load evenly to avoid overloading axles.

Transportation & Logistics

- Use appropriate lashing and securing systems for different cargo types.

- Regularly inspect and maintain load restraint equipment.

- Provide comprehensive driver training on load securing procedures.

Agriculture

- Secure loose items like hay bales and grain bags with nets, straps, or chains.

- Distribute load evenly to protect equipment.

- Adhere to regulations for transporting hazardous materials.

Mining

- Use specialised load restraint systems for heavy equipment and spare parts.

- Implement load securing procedures for both overland and off-road transportation.

- Consider environmental factors when securing loads.

Oil & Gas

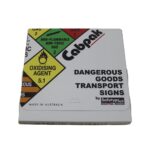

- Secure hazardous materials with appropriate containment and restraint systems.

- Comply with strict safety regulations and industry standards.

- Exhibit the correct Dangerous Goods Labels

- Develop emergency response plans for load-related incidents.

Food & Beverage

- Protect perishable goods with temperature-controlled containers and insulation.

- Use food-grade materials for load restraint to prevent contamination.

- Adhere to hygiene and sanitation standards during loading and unloading.

Retail

- Secure pallets and boxes with stretch wrap, strapping, or shrink wrap.

- Distribute load weight evenly for efficient transportation.

- Use load bars or edge protectors to prevent product damage.

Additional Tips for Effective Load Restraint

- Invest in high-quality load restraint equipment.

- Provide regular training for personnel involved in loading and securing procedures.

- Inspect and maintain load restraint equipment regularly.

- Stay updated on the latest regulations and industry best practices.

By following these industry-specific guidelines and general best practices, you can significantly enhance safety, protect your cargo, and comply with regulations. Remember, proper load restraint is not just a requirement but a crucial aspect of responsible transportation.

You May Also Be Interested In:

10 Essential Tips for Truck Drivers to Stay Awake on the Road

How to Enhance your Supply Chain Management: Transport Companies

Understanding Dangerous Goods Labelling Requirements: A Comprehensive Guide