How To: The Ultimate Guide to Tensioning Webbing and Ratchet Straps

Properly tensioning webbing straps is critical for securing loads safely and efficiently in trucking operations. This guide will explore the methods and best practices for tensioning webbing straps using various tools and techniques.

Types of Tensioning Tools

Webbing straps can be tensioned using three main types of tools:

- Clip-on Winches

- Ratchet Straps (and any other forms of webbing)

- Slide on Winches

Each tool has its specific use case and provides different levels of tension depending on the application.

Factors Influencing Tension

The tension produced by a truck winch or hand ratchet depends on several factors:

- Handle Length: Longer handles provide more leverage, resulting in higher tension.

- Webbing Spool Diameter: As the webbing is tightened, the spool diameter increases, affecting the tension.

- Number of Ratchet Teeth: More teeth typically allow for finer adjustments and higher tension.

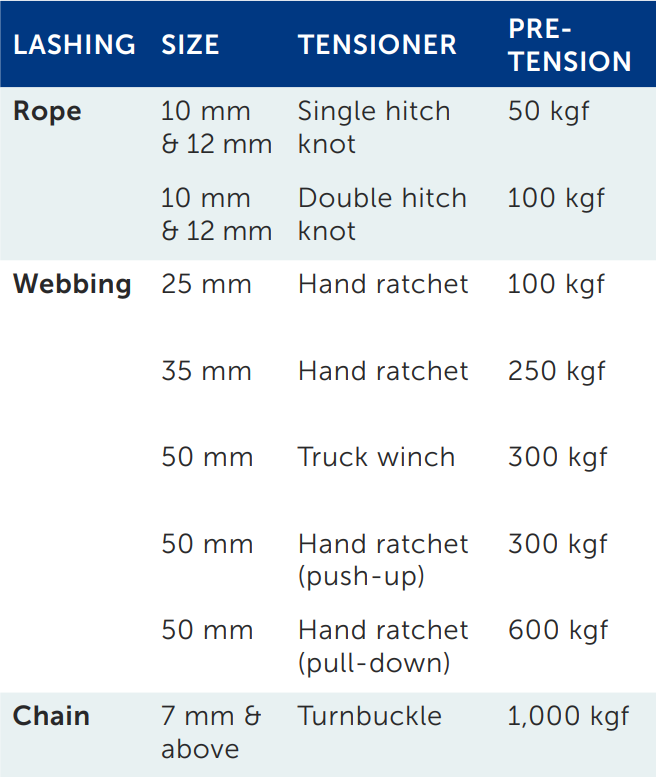

The NHVR has a guide to average pre-tensioners for standard equipment:

Hand Ratchets vs. Truck Winches

Hand ratchets that operate by pulling the handle downwards generally produce more pretension (600 kgf) than push-up ratchets and standard truck winches (300 kgf).

Maximising Tension

For higher tensions, loop the strap over a standard triangular end fitting. This method can double the lashing capacity and increase pretension by an extra two-thirds.

Best Practices for Tensioning

- Hand Ratchet Winches: Ensure there are at least one and a half turns of strapping on the spindle, and no more than three, for effective pretension.

- Long Lashings: Using longer lashings can help maintain consistent high tension since the ‘draw-in’ length between each click of a webbing ratchet is more manageable than with short lashings.

- Even Winding: Make sure the strapping is wound evenly across the drum of the winch or ratchet. Uneven winding can significantly decrease the effectiveness of the tensioner as the layers of webbing become thicker, shown in Figure 417.

Regular Checks and Maintenance

- Check for Knots and Twists: Ensure there are no knots or twists in the strapping. While webbing straps should not be excessively twisted, a half-turn can help prevent vibration and flapping (Figure 418).

- Inspect for Damage: Look out for signs of wear such as furriness, cuts, abrasions, and damaged stitching. Any webbing that appears furry or has visible damage should be replaced immediately.

Checklist for Certifiers and Designers

When assessing the serviceability of webbing and attachments according to AS4380, the following conditions necessitate replacement:

- Webbing weakened by 10% or more of its original minimum breaking strength due to wear, damage, or exposure to chemicals, high temperatures, or prolonged sunlight.

- Unapproved repairs to webbing.

- Attachments weakened by 10% or more, or prevented from functioning by wear, damage, or corrosion.

Proper tensioning of webbing straps is essential for the safety and security of loads in trucking operations. By using the right tools and following best practices, you can ensure optimal performance and longevity of your webbing straps. Regular inspections and maintenance are crucial to identify and address any issues promptly, keeping your operations running smoothly and safely.