Transporting vehicles and mobile equipment requires adherence to safety standards to ensure secure transit and prevent accidents. This guide, based on best practice demonstrated in the Load Restraint Guide, provides an overview of the best practices for restraining rubber-tyred, steel-wheeled, and tracked vehicles.

Manufacturer’s Recommendations

Always start by consulting the manufacturer’s loading and restraint recommendations. These are designed to be compliant with Australian or ISO load restraint regulations and include designated lashing points for secure attachment.

Transporting Small and Large Equipment

Small vehicles and equipment should be transported on general freight vehicles, while large or tall items are best suited for low loaders to enhance stability.

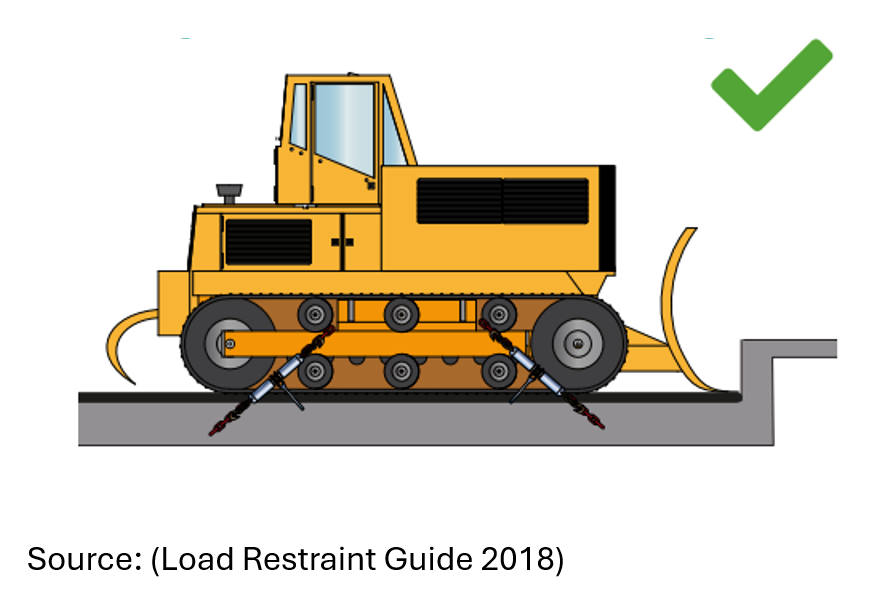

Direct Restraint Methods

Whenever possible, use direct lashings combined with blocking to restrain the equipment. Ensure that all lashings are of the same type and length and positioned at equivalent angles to distribute tension evenly.

Containment

As an alternative to direct lashings, vehicles and equipment can be contained within the body structure of the carrying vehicle, providing an additional layer of security.

Lashing Techniques

- Loop chains around suitable parts of the load, such as designated lifting or lashing points, ensuring sufficient clamping.

- Avoid looping chains over sharp edges; instead, use rounded corner protectors or reposition for a straight line pull.

- Lashing points should be color-coded or labeled, with their restraint capacity clearly specified.

Towing Brackets and Lashing Points

Utilise front and rear towing brackets as lashing points, ensuring that attachments cannot loosen during transport. Use appropriately rated shackles instead of round pins to connect chains and prevent damage.

Lifting Lugs and Winches

Do not use lifting lugs as lashing points if they are unsuitable for the chosen load restraint method. For wire rope lashings, ensure winches have a positive locking feature and do not rely solely on hydraulic pressure.

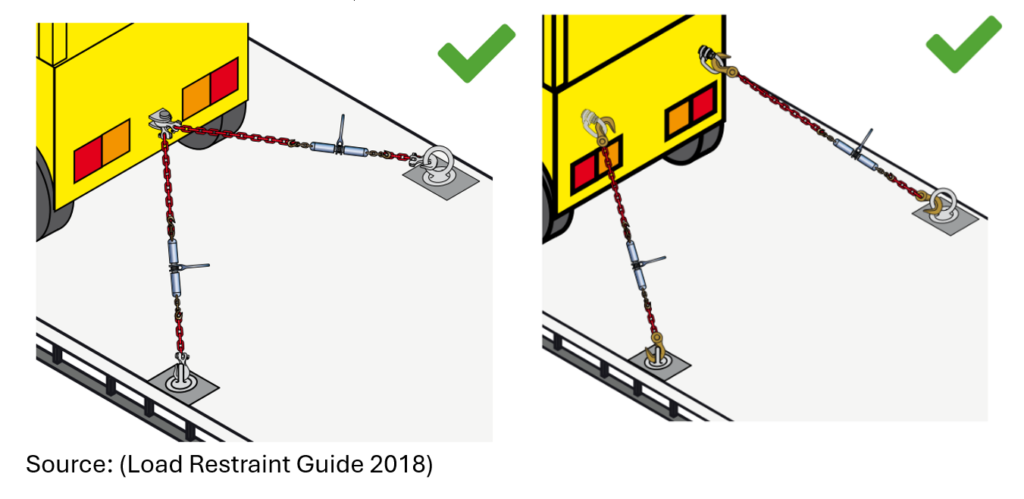

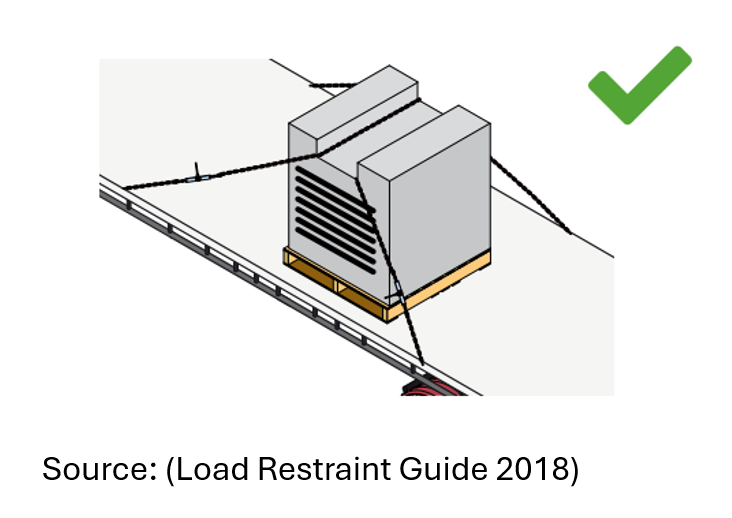

Sideways Restraint

To provide adequate sideways resistance, attach two separate lashings directly to the vehicles or equipment. Avoid using a single lashing passed across the deck through a lashing point, as it will not effectively restrain sideways movement.

By following these guidelines and ensuring that all methods are certified by an engineer, you can transport vehicles and mobile equipment safely and in compliance with performance standards.