[vc_row][vc_column][vc_column_text]

Protect A Load Friction Mat Testing

Date : 16/01/2018

Ref: E00728

Author: Paul Dore,

BEMech, MIEAUST

Logistics Engineer, Engistics

Tel 0437 988 148

Reviewed: Mike Robertson

BEMech, CPEng, RPEQ

Managing Director, Engistics

Tel 0425 001 086

[/vc_column_text][vc_column_text]

Report Contents/Overview

Introduction and Purpose of Testing

Introduction and Purpose of Testing- Background – Tie Down Restraint

- Equipment and Set-up

- Methodology

- Results and Observations

- Conclusion

Introduction/Purpose of Testing

- Engistics has been engaged by Protect A Load to assist with testing the

coefficient of friction of their Transport load matting (“Protect A Load Friction

Matting”). - Typical Australian trailer decks are made of steel and load matting is used to improve the grip between the load and the steel deck.

- The friction coefficient is a measure of the ‘grip’ between two surfaces. To

determine this friction coefficient, we conduct tests by dragging loads and measuring the forces involved. - Tests to determine the friction coefficient have been conducted in both wet and dry conditions.

- The test results published in this report only apply to the particular type of matting tested.

- Protect A Load should be aware that these results do not apply to other

types of matting/rubber and should ensure matting types and manufacturer/suppliers are not changed without confirming equivalent friction.

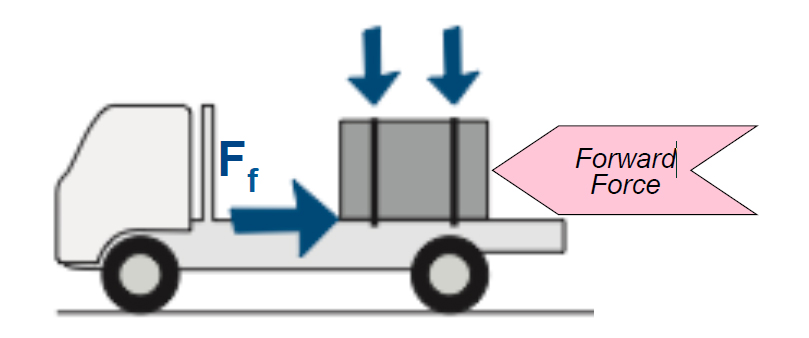

Background – Tie-down Restraint

- Understanding Friction is critical for the tie-down method

- Friction is the force that resists motion (grips) between two surfaces

The Straps pull DOWN! and Friction Holds the Load BACK!

Friction is a function of only:

- The friction factor (Usually called the

friction Coefficient) – the “grip” between two

surfaces, and - The down-force

Down-force is a combination of:

- The weight of the object

- The vertical

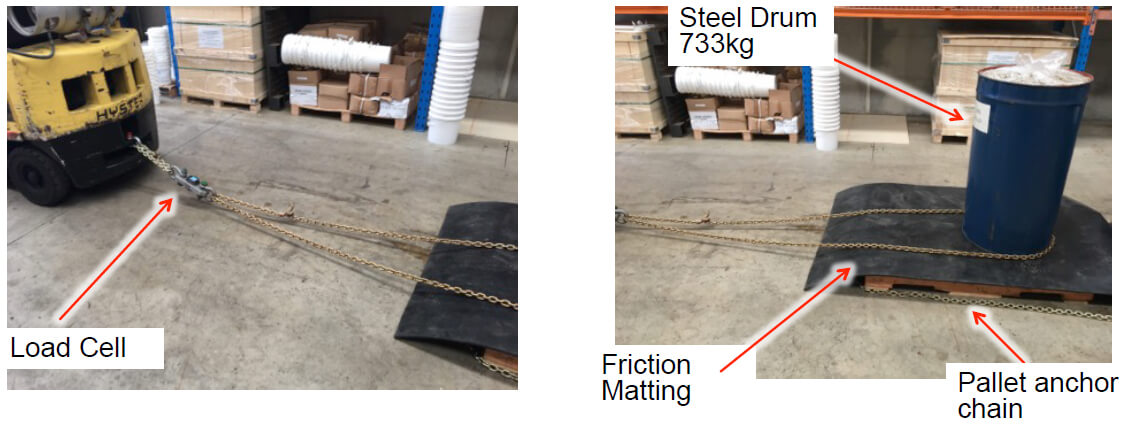

Equipment and Test Setup:

- To measure the friction coefficient, a steel drum has been dragged across the matting.

- The force required to drag the drum compared to the actual weight of the drum is a measure of the friction coefficient

[/vc_column_text][vc_column_text]

Friction Coefficient = Drag Force (kg.f) / Drum Weight (kg)

Equipment and Test Setup:

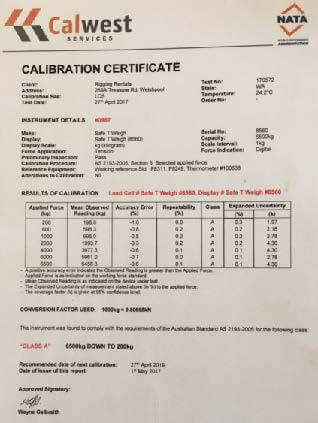

Load Cell Calibration Certificate

[/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text] [/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text] [/vc_column_text][vc_column_text]

[/vc_column_text][vc_column_text] [/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Equipment and Test Setup: Test Weight Measurement

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text] [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text]

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text]

- The steel drum was measured to be 733kg.

- The drum was observed to be smooth on the underside and free of significant corrosion.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Methodology:

[/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text] [/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]

- The load cell was setup in-line with the load.

- The ‘Peak hold’ function was used to measure the tension at the point of load movement.

- 5x tests were repeated with both wet and dry matting

- The static friction coefficient was determined as below:

[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Friction Coefficient = Drag Force (kg.f) / Drum Weight (kg)

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]

- Generous amounts of water were poured onto the rubber (below the drum) before repeating the test.

- Lower friction coefficients were observed with water on the surface of the rubber.

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

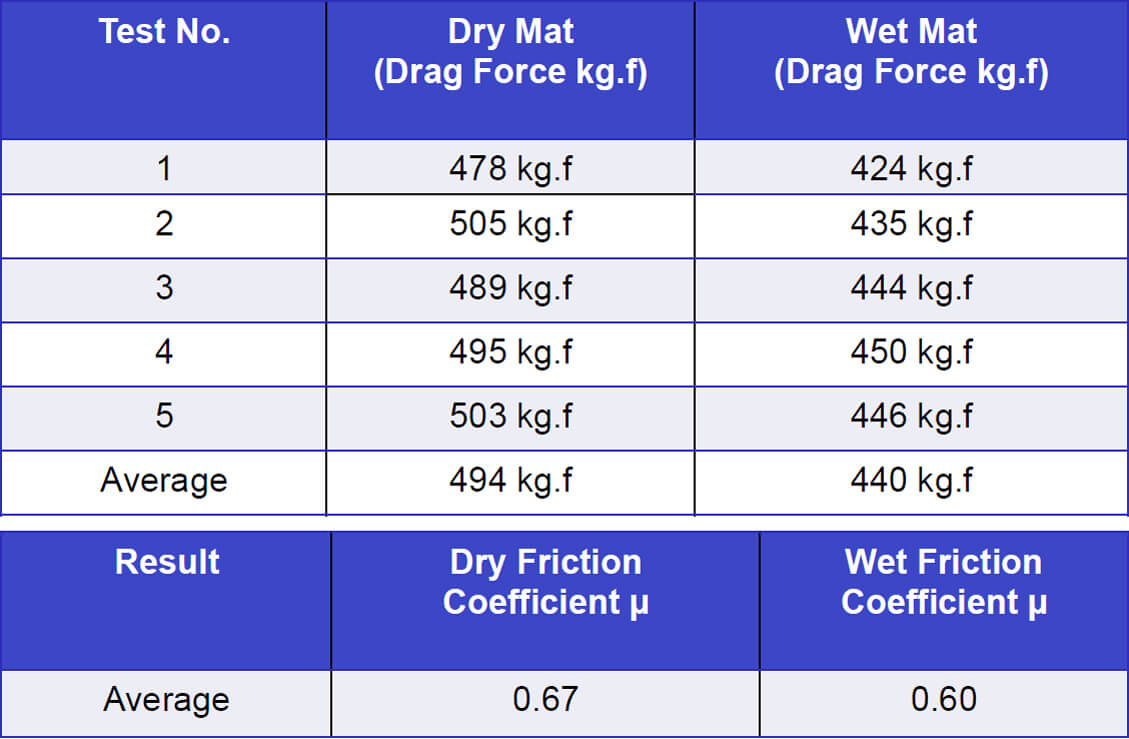

Results and Observations:

Tests showed pleasing consistency of results.

Photo of test surface – After test Completion

- The mat surface was smooth and free of any surface wearing on completion of the test.

- The drum did not bite into the matting. Results obtained are a true value of the steel/load mat friction coefficient.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Conclusion

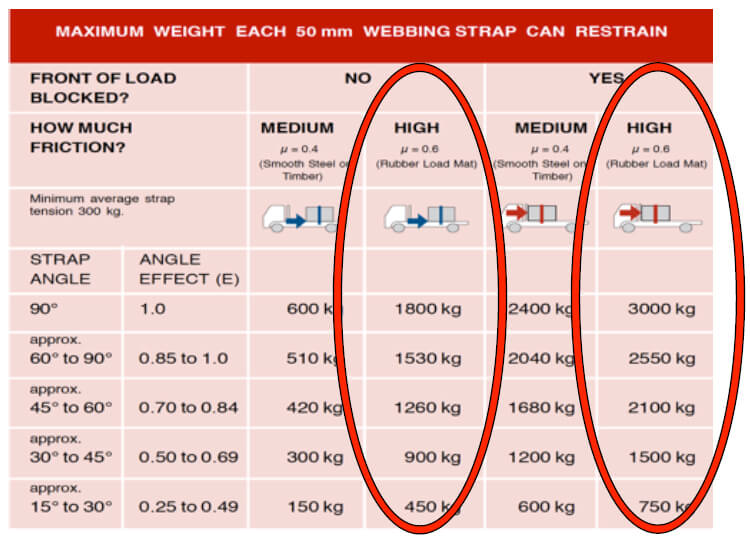

- The average coefficient of friction between the Friction Matting and a steel drum was determined to be μ=0.67 dry and μ = 0.6 wet

- Engistics recommends utilising the wet coefficient of friction only for determining tie down restraints.

- Testing has shown the rubber to be capable of achieving a consistent high level of friction.

Please note that to achieve adequate restraint, additional consideration needs to be given to:

Please note that to achieve adequate restraint, additional consideration needs to be given to:

- Blocking

- Pre-tension

- Lashing Angles

- Weight of the Load

[/vc_column_text][/vc_column][/vc_row]